- Servicing : United States Of America

- Mail : scott@dampprotectsystems.com

Case study

Diocletian's Palace

General information:

Location: Split, Croatia

Year of construction: approx. 295

Size: Outer walls: 175-181 x 216 m

In 1970 the palace was listed on the UNESCO World Heritage List because of its value

History:

It has not been established when exactly the construction of Diocletian’s Palace began. It is supposed that this was around the year 295. It is not known the architect, nor the builders of the palace were. However, the carved Greek names Zotikos and Filotas, as well as numerous Greek letters indicate that a certain number of builders descended from the eastern part of the Empire, i.e. that Diocletian brought along craftsmen from the East. The basic construction material came from the immediate vicinity. White limestone was supplied from the island of Brač, and to some extend from Seget near the town of Trogir. The building as a whole had no immediate model in Roman architecture up to then.

The problem:

The effect of capillary damp, the presence of other types of moisture and their suppression

Diocletian’s Palace has been exposed to capillary moisture, penetration of rain and catchment water for many years (centuries). This resulted in great construction damage and deterioration of this very valuable cultural monument.

The signs of the effect of capillary damp were easily noted by touring and examining the building. The clear signs of growing humidity are: the unpleasant smell of moisture, mould, falling of paint and plaster from the walls, the emerging of lime and nitrates on the wall surface, extremely cold areas and walls cold to touch.

The consequences of this are danger to the health of people who reside in such areas and the deterioration of the building itself. The dampness of the walls constantly varies (increases and decreases) depending on the favourable, or unfavourable conditions in the area. Such conditions are caused by precipitation and the seasons (winter, spring, summer, autumn). Each of the seasons brings its own conditions which are different from the previous period.

Constant pulsing and creating of processes which influence the structure of construction material

The increase and decrease of humidity leads to alternating between drying and soaking and expansion and shrinking of sand particles found in construction material. As water is a universal solvent, it expends walls by dissolving minerals, and releases their elements into the biochemical cycle.

The chemical effects of nitrate salts, which are left on the wall surface after evaporation, break, layer and transform the construction material into a pasty mass, whereby the binding power of the material is lost.

Solution:

In 2008 the sanation of capillary damp started using the PROsystem system.

Results:

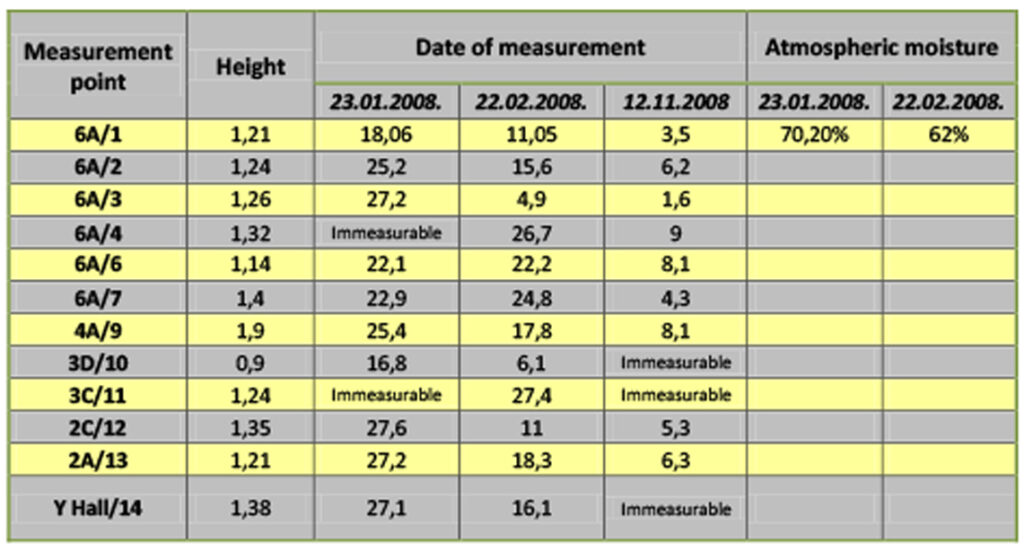

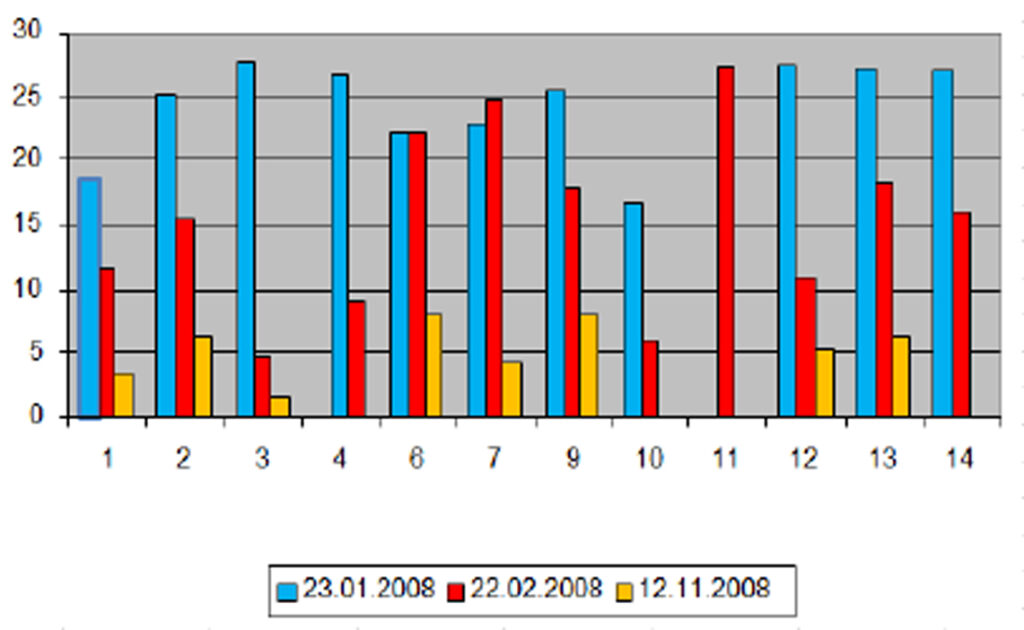

The results of measurements after the installation of the PROsistem machines

Owing to PROsystem, in the parts of the building where the machines were installed, the capillary damp is effectively and quickly retreating partly withdrawing some of the salts, depending on the structure of the material, porosity of the walls and the composition of the soil. The process of drying has started, which is visible on the building itself. The duration of the process depends of the type and porosity of the material, wall thickness, water permeability of the ground and conditions in the atmosphere. The results measurements after the installing of PROsystem machines confirm this

The results of the measurement of capillary moisture using the electronic method. (independent measurement)

At all measurement points progress has been noticed in the drying out of capillary damp, except on the place where catchment water, which come from the ceiling and are caused by precipitation, where the result is approximately the same, but the drying out process will nevertheless be much shorter due to the lack of capillary moisture within the walls. The space seems to be more airy, the air is of a higher quality because the unpleasant smell has disappeared.

Part of the space infested by mould and moss will be much smaller because of the lack of capillary moisture and the moisture it creates in the space, so it will dry out. The salts and the saltpetre which were visible and sticky like a paste in certain places have, due to the lack of moisture, started to dry and become solid.

23.01.2008.

22.02.2008.

Conclusion:

As it is visible, the results are excellent. The deterioration of the building resulting from capillary damp has been restrained. The PROsystem system must be permanently installed in the building so that the cause of the problem – capillary damp – would not return.

Call Today For A Free Estimate

Contact Details

- Phone Number

+1 949 234 8111

- Email Address

scott@dampprotectsystems.com

- Location

- Business Hours

Mon – Sunday: By Appointment

© 2024 All rights reserved by Damp Protect Systems